Refrigerated and heatless are two broad categories of air dryers available these days. Talking about air dryers remains incomplete without mentioning the concept of dew point temperature. It is the unit used to measure the dryness of compressed air. At this temperature, the moisture present in the compressed air in vapour form condenses to form liquid. Similarly, pressure dew point temperature and atmospheric dew point temperature are the two distinct temperatures of compressed air when under any kind of pressure and atmospheric pressure respectively. When we talk about the most advanced and cheapest mode of drying compressed air, refrigerated air dryers are quintessential.

Refrigerated and heatless are two broad categories of air dryers available these days. Talking about air dryers remains incomplete without mentioning the concept of dew point temperature. It is the unit used to measure the dryness of compressed air. At this temperature, the moisture present in the compressed air in vapour form condenses to form liquid. Similarly, pressure dew point temperature and atmospheric dew point temperature are the two distinct temperatures of compressed air when under any kind of pressure and atmospheric pressure respectively. When we talk about the most advanced and cheapest mode of drying compressed air, refrigerated air dryers are quintessential.

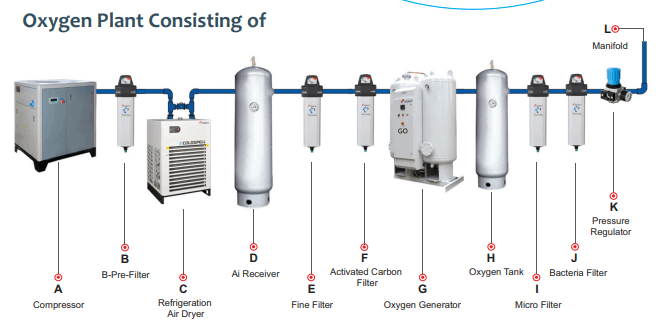

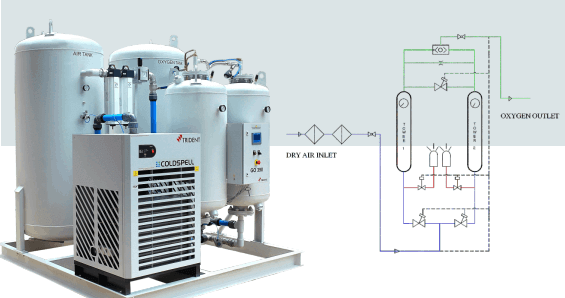

Oxygen plant works on the Pressure Swing Adsorption (PSA) technology. The moisture free air centers into the zeolite towers where the nitrogen and other gases are adsorbed and thus only oxygen at the desired purity level is delivered at the outlet.

Generation Cycle : Purified (Moisture and oil free) air from the compressed air system, passes through one of the tower filled with molecular sieves (Zeolite type). The sieves selectively adsorbs nitrogen, allowing oxygen to pass through at the desired purity level.

Regeneration Cycle : During regeneration cycle, the sudden depressurization brings out nitrogen molecules trapped in the sieves pores to the surface of the beads. Small portion of the oxygen from the drying tower is passed over the sieves through the regeneration orifice. This results in complete regeneration of molecular sieves and the trapped gases are completely exhausted.

The automatic cycling of the adsorption and desorption between the two beds enables the continues production of oxygen.

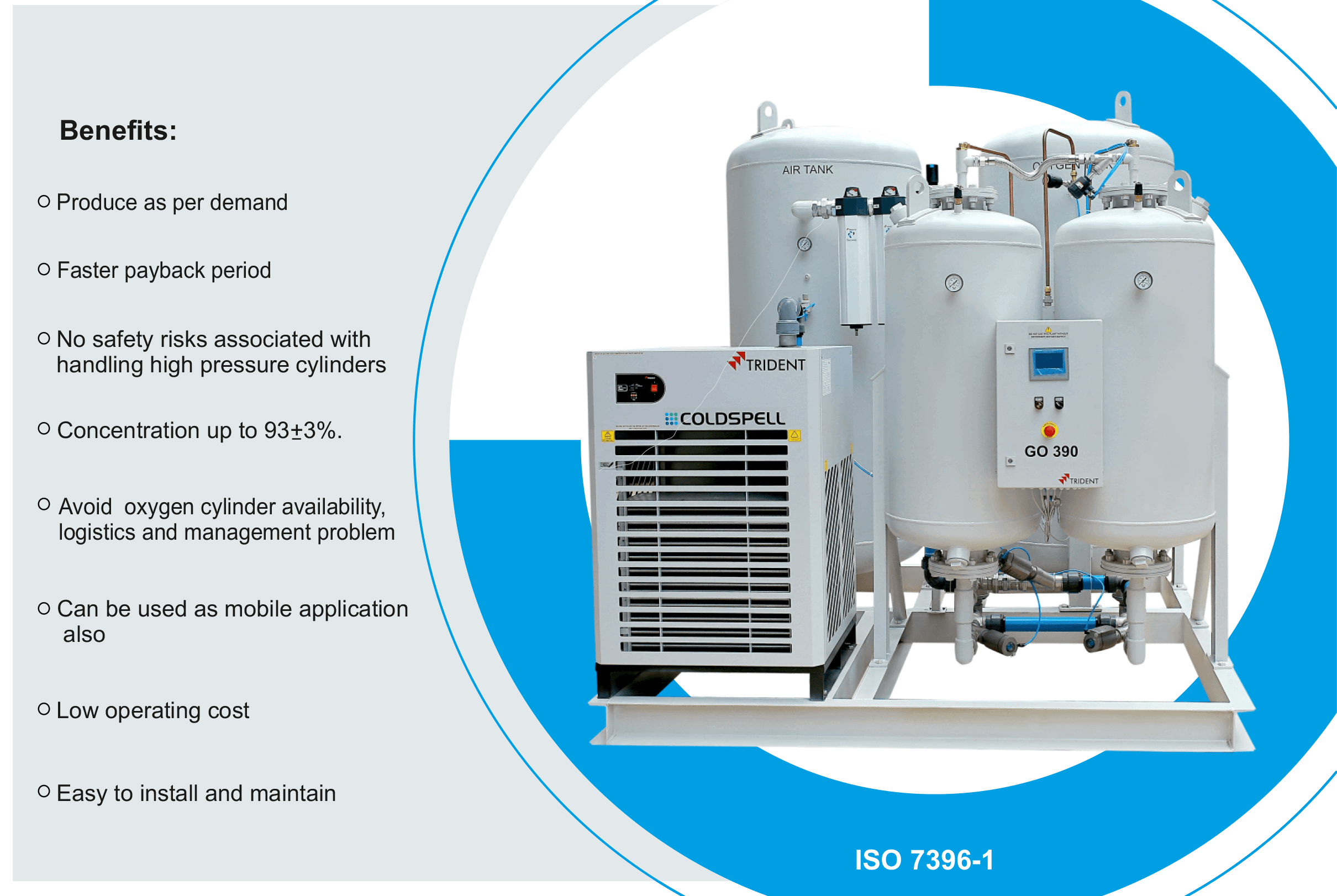

Trident’s PSA medical oxygen generator Plant are designed in such way, it will work at site 24 x7 without any trouble. All the components used in product are highly reliable and tested as per the Industrial standards. All the safety precautions have been addressed (stand by gas supply mode automatically in case of any failure mode like purity, power failure etc.) to give uninterrupted gas supply.

Trained service team are available across the country to attend the service calls for breakdown as well as preventive maintenance.

Necessary documents and training will be provided to users to handle minor breakdowns.

| Factor | Medical oxygen Manufacturers using PSA | Liquid oxygen supply systems | High-Pressure cylinder |

|---|---|---|---|

| Capital costs | Investments Required by; but payback period (compared with high-pressure cylinders)less than 15 months | Investment required | Investment not required |

| Recurring costs | Electricity | Cost of liquid medical oxygen and rent | Cost of medical oxygen |

| Space requirements | Medium | High | Least; but depends on number of cylinders |

| Administration | Easy | Difficult | Difficult |

| Safety | Safe | Risk of uncontrolled release of oxygen | Risk of explosion |

| Logistic management | One-time-installation of the plant | Issues might arise when a tanker needs access to bulk-storage tank to refill liquid ozygen | Issues might arise with the transport, storage and accessing of the cylinders |

| Evaporation loss | None | Up to 20% | 3% of unusable |

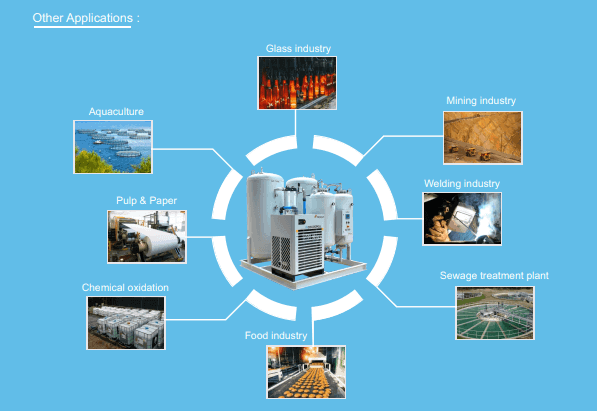

Oxygen is the most important clinical gas used in health care centers and Hospitals. No modern hospital can manage without PSA medical oxygen generator. Pure oxygen is an essential resource in the operating room during anesthesia, for the respiration of patients, and in the intensive care or neonatal units. The constant high demand for this gas renders substantial expenses for hospitals. Currently, hospitals buy oxygen from bulk medical oxygen plant Manufactures. The bulk oxygen is bought in both liquid and gaseous form. These sources of oxygen can become an economic burden as large hospitals can spend more money in a year on oxygen supply alone.

Fortunately, Medical oxygen can be generated on-site in any hospital, clinic, or health care center in a much more cost effective manner. Using pressure swing adsorption method oxygen is generated and it is being used, thus enabling a health care center to be self-sufficient in meeting its oxygen demand.

PSA medical oxygen generator methods are capable of producing oxygen in medium capacity. This is ideal for an on-site Medical oxygen generator hospital unit, because it is a safe process with reasonable energy and area requirements. And acceptable as per USP and Global standards. (Read Catalouge for detailed Principle and Details). on site Medical oxygen generator by Trident, provides bulk oxygen cylinder to the hospital for medical use which is cost-effective and also most reliable.

Copyright© 2023 by TRIDENT PNEUMATICS All Rights Reserved